| Model | KBSG |

| Transformer Type | Dry type |

| Voltage | 6 KV/0.4KV |

| Frequency | 50/60Hz |

| Number of Phases | 3 phases |

| Coil Material | Copper/Aluminum |

| Insulation Class | H/C |

| Connection Method | Yyo/Dyn11 |

| Cooling Method | AN,GNAN |

| Protection Class | IP54/IP65/IP66/IP67 |

| Explosion-Proof Type | Exd |

| Rated Capacity | 100KVA |

| No-load Loss(KW) | 520 |

| load Loss(KW) | 920 |

| No-load Current (%) | 2.5 |

| Impedance Voltage(%) | 4 |

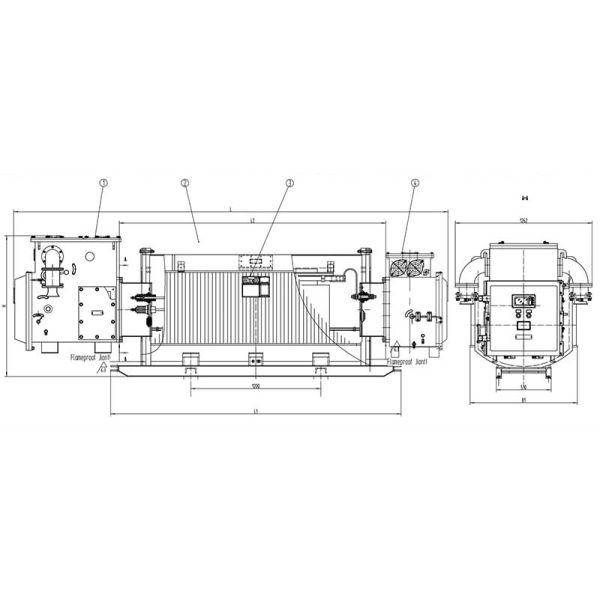

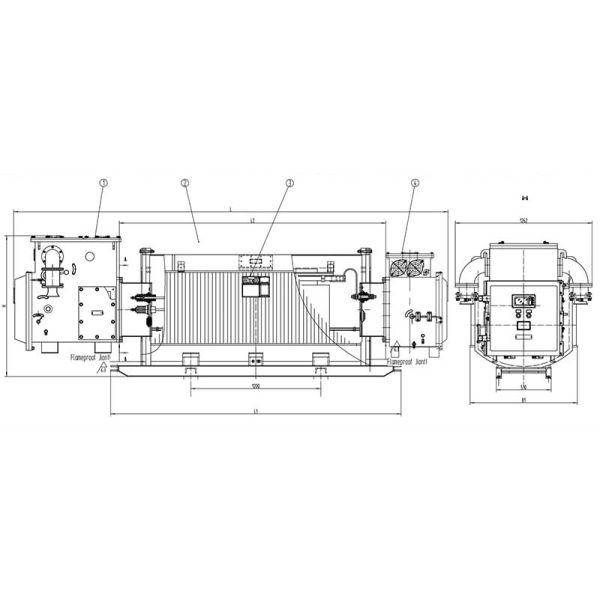

| Outline Dimension | 2500*950*1430 |

| Weight (KG) | 1600 |

Focus on "Environmental Adaptability" – Engineered for Extreme

Underground Conditions

The Critical Challenge: How Harsh is the Underground Environment?

We Fully Adapt

Underground mining is not a standard electrical environment. It is

a hostile domain characterized by methane accumulation, pervasive

coal dust, high humidity (≤95% @25℃) , and constant vibration

(vertical inclination ≤15°) . In these conditions, standard

transformers are prone to corrosion, mechanical loosening, and

catastrophic failure.

The HENTG POWER KBSG Series Mining Explosion-Proof Dry-Type

Transformer is engineered with "Environmental Adaptability" as its

core design philosophy. From material selection to structural

integrity, it is fully tailored to meet underground demands,

ensuring power supply equipment maintains unwavering stability in

high-risk environments.

Key Environmental Adaptability Parameters Explosion-Proof Grade: Exd I / Exd I Mb Humidity Resistance:

Relative humidity ≤95% (at 25℃) Vibration Adaptation: Vertical

inclination ≤15°, anti-loosening structure Temperature Adaptation:

Ambient -20℃ to +40℃; Insulation resistance ≥135℃ Protection

Rating: IP54-IP65 (Dustproof and Waterproof)

Core Advantages: Fearless in Harsh Conditions, Durable, and

Resilient1. Confronting Explosion Risks: Adapted for Flammable Gas & Dust

• Targeting the hazards of methane and coal dust explosions, this

product has achieved Exd I / Exd I Mb explosion-proof certification

and fully complies with the GB 3836 "Electrical Equipment for

Explosive Atmospheres" standard. It can be deployed directly in

Class I explosive hazard areas within underground coal mines,

eliminating the risk of ignition via electric sparks. • Versatile

Application: Suitable for Zone 1 and Zone 2 explosive dust areas,

ensuring safe operation in both coal mining faces and metal mine

crushing roadways.

2. Withstanding Severe Climates: Moisture-Proof,

Corrosion-Resistant, Vibration-Proof

• High Protection Rating (IP54-IP65): The fully sealed structure

effectively blocks coal dust intrusion, while the waterproof design

handles underground water spraying scenarios. Even in prolonged

high-humidity environments, internal components remain protected

against moisture and corrosion. • Specialized Anti-Corrosion

Coating: The shell features a mining-specific anti-corrosion paint

that resists erosion from acidic/alkaline gases, significantly

extending the equipment's service life. • Vibration-Resistant

Structure: The iron core assembly is secured with channel steel

clamps and tension screws, while a specialized coil compression

device prevents loosening. It withstands underground mechanical

vibrations (vertical inclination ≤15°), preventing failures caused

by component displacement.

3. Adapting to Complex Conditions: Temperature & Altitude

Compatibility

• Wide Temperature Operation: Tolerates ambient temperatures from

-20℃ to +40℃, with internal insulation materials capable of with

standing temperatures exceeding 135℃. It will not succumb to

overheating, even in local high-temperature zones (e.g., near heavy

mining machinery). • Low-Altitude Adaptation: Supports operation in

mining areas at altitudes ≤2000 meters without parameter

adjustments. It maintains stable output even in plateau mining

regions such as those in Mongolia and South Africa.

4. Diverse Scenario Application: From Coal Mines to Tunnels

• Underground Coal Mines: Powers mining faces, ventilation systems,

drainage pump stations, and hoist support. • Metal/Non-Coal Mines:

Supplies power for roadway lighting, crushing equipment, and

electric traction machinery. • Tunnel Projects: Supports tunnel

construction ventilation, drainage, and temporary lighting systems.